Cooling Tower Side Stream Filtration

Typical Applications

- Inline system

- Pond to Pond system

- Blow down alternate

- In recirculation line

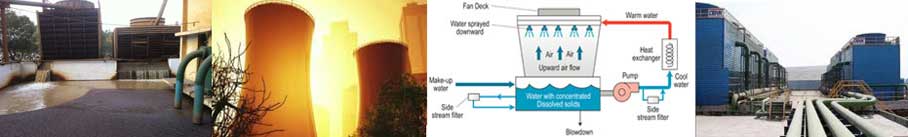

Cooling towers are an integral component of many industries , providing comfort or process cooling across a broad range of applications. Cooling towers represent the point in a cooling system where heat is dissipated to the atmosphere through evaporation. Cooling towers are commonly used in industrial applications and in large commercial buildings to release waste heat extracted from a process or building system through evaporation of water.

Cooling tower systems operation is most efficient when the heat transfer surfaces are clean. However, these are dynamic systems due in part to their operating environment and because of the nature of their application. Cooling towers operate outside and therefore are open to the elements, making them susceptible to dirt and debris carried by the wind. Further, they often experience wide load variations and their operation can be significantly influenced by the quality of the water used for makeup in the system.

The combination of process and environmental factors can contribute to four primary treatment concerns encountered in most open-recirculating cooling systems: corrosion, scaling, fouling, and microbiological activity. As shown in Figure, these treatment concerns are inter-related such that reducing one can have an impact on the severity of the other three.

Corrosion: Corrosion is an electrochemical or chemical process that may lead to the premature failure of system metallurgy.

Scaling: Scaling is the precipitation of dissolved mineral components that have become saturated in solution, which can lower efficiency of the system.

Fouling: Fouling occurs when suspended particles or biologic growth forms an insulating film on heat transfer surfaces. Common foulants include organic matter, process oils, and silt, which can also lower system performance. Microbiological Activity: Microbiological activity refers to microorganisms that live and grow in the cooling system that can contribute to fouling and corrosion.

WyunaSep Side stream filtration systems reduce suspended solids and debris in the system cooling water, which leads to less fouling in the system. Decreasing suspended solids can also help reduce biological growth in the system because suspended solids are a good source of food for microbiological organisms. Decreasing biological growth in turn helps to reduce microbiologically influenced corrosion. In addition, scaling can be reduced from side stream filtration by limiting fouling and corrosion byproducts which can also contribute to scale formation on the heat exchange surfaces. Effectively managing these conditions can optimize system performance, often resulting in moderate to significant energy and water savings.

Full flow and side stream filtration are the two most common methods used to filter the water that is pumped into the circulation systems. Full flow filtration uses a filter installed after the cooling tower on the discharge side of the pump. This filter continuously filters all of the recirculating system water in the system. Inherently, the filter must be sized to handle the system’s design recirculation rate. Side stream filtration, on the other hand, continuously filters a percentage of the flow instead of the entire flow. It can be a cost-effective alternative to full flow filtration that can easily improve the water quality to reduce water consumption and ensure efficiency of the cooling systems. And unlike full flow filtration, side stream filtration systems can be cleaned while the cooling systems are online, avoiding the need for planned downtime.

WyunaSep Side Stream Technology Characterization

WyunaSep Side stream filtration systems continuously filter a portion of cooling water to remove debris and particles. Filtered water is then pumped back into the main condenser line through a nozzle or returned to the cooling tower basin (called the sump). Figure below shows a simplified cooling tower schematic, including the two example locations where side stream filtration can typically be installed.

These systems remove suspended solids, organics, and silt particles for a portion of the water system on a continuous basis, reducing the likelihood of fouling and biological growth, which helps to control other issues in the system such as scaling and corrosion. This improves system efficiency and often reduces the amount of water rejected from the system. WyunaSep Side stream filtration increases water and energy efficiency and reduces cost, as described below.

Reduction in water consumption

Demand for makeup water in cooling towers is decreased with an increase in the system’s cycles of concentration. Essentially, higher cycles of concentration mean that water is being recirculated through the system longer before blowdown is required. Less blowdown reduces the amount of makeup water required in the system, resulting in water savings.

Reduction in energy consumption

Side stream filtration reduces the likelihood of scale and fouling on the heat exchangers. Even the smallest layer of scale or fouling on heat exchange surfaces can reduce the rate of heat exchange, forcing the system to work harder to achieve the required cooling.

Reduction in chemical use

A side stream filtration system can remove suspended particles, reducing the need for additional chemical treatment such as dispersants and biocides.

Lower maintenance cost

Traditionally, cooling towers are cleaned by draining the tower and having the sediment removed mechanically or manually from the basin or sump. Cooling systems that are cleaned via side stream filtration routinely provide longer periods of continuous operation before being taken offline for required maintenance.

Improvement in productivity and reduction in downtime: When a cooling system is fouled or has scale buildup, production may be slowed due to inefficient heat exchange equipment. In some cases, the cooling system and heat exchange equipment may need to be taken offline for repairs, decreasing production.

Control of biological growth

Biological growth control and reduction can mitigate potential health

Advantages of Side stream filtration

- Reduction in water consumption

- Reduction in energy consumption

- Reduction in chemical use

- Lower maintenance cost

- Improvement in productivity and reduction in downtime

- Control of biological growth