How it Works

Principle of Operation

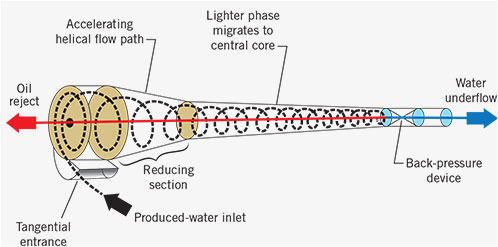

The Feed stream enters the Wyuna Deoiling Hydrocyclone through a tangential inlet. Its velocity is converted into tangential velocity in the inlet area, imparting a centripetal force on the fluids. As the fluid moves down the conical section, tangential velocity increases as does the centrifugal force. The oil and water separation is magnified since the ratio between the centrifugal force in the hydrocyclone and the force of gravity is in excess of 1000, meaning the force is 1000 times greater in the hydrocyclones.

The heavier water phase, which is subjected to higher centrifugal forces, moves to the outer wall of the cyclone and exits the tailpipe of the WyunaSep hydrocyclone by the underflow. The lighter particles, free-oil droplets, are displaced towards the inner core of the cyclone and move axially up the cyclone and exits out the reject orifice as overflow. By maintaining a balanced differential pressure between the overflow and underflow, the oil core is forced out through the overflow outlet.

Where: Vp = particle rising or settling velocity, cm/sec

G = gravitational constant, 980 cm/sec2

μ = absolute viscosity of continuous fluid, poise

dp = density of particle (or droplet), gm/cm2

dc = density of continuous fluid, gm/cm2

D = diameter of particle, cm

A negative velocity is referred to as the particle (or droplet) rise velocity.

Assumptions Stokes made in this calculation are:

1) Particles are spherical

2) Particles are the same size

3) Flow is laminar, both horizontally and vertically. Laminar flow in this context

means flowing gently, smoothly, and without turbulence.

From the above it may be seen that the variables are the viscosity of the continuous liquid, specific gravity difference between the continuous liquid and the particle, and the particle size.

The rise rate of oil droplets is also governed by Stokes's Law. If the droplet size, specific gravity, and viscosity of the continuous liquid are known, the rise rate may be calculated.

To calculate the size of an empty vessel gravity separator, it is first necessary to calculate by the use of Stokes's Law the rise velocity of the oil droplets.

The size of the separator is then calculated by considering the path of a droplet

entering at the bottom of one end of the separator and exiting from the other end of the separator. Sufficient volume (residence time) must be provided in the separator so that an oil droplet entering the separator at the bottom of the inlet end of the separator has time to rise to the surface before the water carrying the droplet exits the opposite end of the separator.

This oil water separator relies on strong centrifugal forces for oil separation. Other oil water separators, like coalescing plate packs, petrol interceptors or similar oil separators, rely on weaker gravitational forces for oil separation.

The centrifugal force generated inside the vortex of the Wyuna deoiling separator is in the order of 1,000 times the force of gravity! With such force, effective oily wastewater treatment can be achieved even with emulsified oil droplets.

Wyuna has a range of solutions to suit your performance requirements and budget. Tell us your discharge requirements, and we can design a solution to meets your needs.